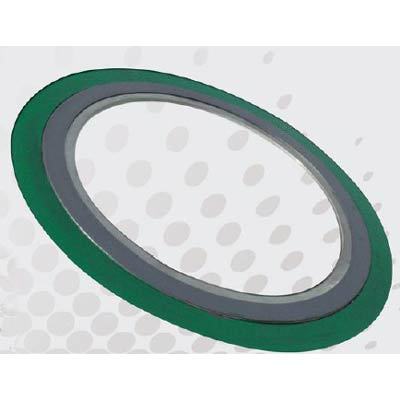

Spiral Wound Gasket

10-10000 INR/Piece

Product Details:

- Usage For Industrial Use

- Product Type Wound Gasket

- Shape Ring Gasket

- Click to View more

X

Spiral Wound Gasket Price And Quantity

- 1 Piece

- 10-10000 INR/Piece

Spiral Wound Gasket Product Specifications

- Wound Gasket

- For Industrial Use

- Ring Gasket

Spiral Wound Gasket Trade Information

- 200 Piece Per Day

- 1 Week

- All India

Enter Buying Requirement Details

Other Products in 'Sprial Wound Gasket' category

|

LEAK CONTROL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS